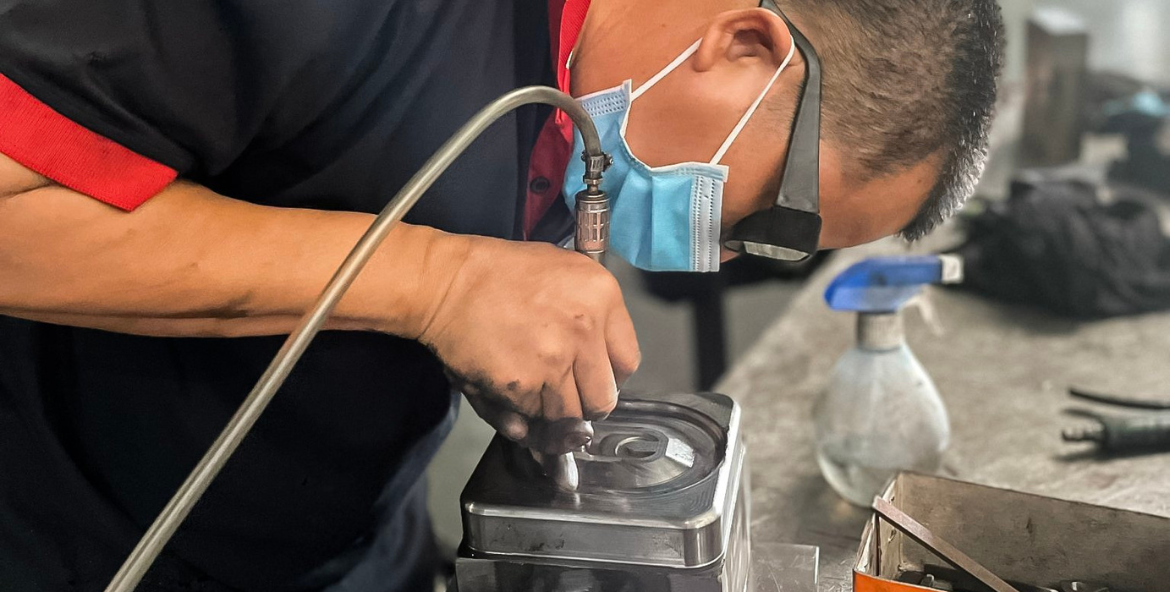

Die Welding

We employ advanced welding technologies, including robotic, manual, TIG, MIG, and MAG welding, to facilitate cost-effective, highly repeatable manufacturing processes

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

Trustworthy Manufacturer Delivering Superior Welding Services

Unlike other manufacturers who simply follow blueprints, our dedicated team is deeply involved in every step of production. We’re renowned for our unwavering focus on top-notch quality, serving various sectors such as automotive, powersports, and construction. Utilizing state-of-the-art robotic welding alongside traditional manual methods, we excel in crafting frames, suspensions, and vehicle winterization solutions, among other products.

Diverse Welding Processes, Each Epitomizing Superior Craftsmanship

As a premier international welding firm, we specialize in a wide array of services to meet our clients’ needs. This includes robotic welding for precise tasks such as resistance spot welding and high-production arc welding, mechanical welding for inaccessible areas, and TIG

Why Choose TopPoint For Mold Welding?

Together with key engineering personnel, the company has a total of more than several decades of experience in the field of mold welding.

- Our facility boasts several automated welding lines, enabling seamless support for high-volume projects, thereby enhancing speed, efficiency, and precision.

- We provide comprehensive support throughout every stage of component production, ensuring quality, consistency, and effective supplier management across all project phases.

- Our seasoned team adeptly adheres to ISO welding standards as well as customizes compliance to meet customer safety and quality specifications.

The Die Welding Capability

Continuing our commitment to providing comprehensive solutions, we are pleased to announce the integration of our die welding facility. This addition brings substantial benefits to our customers, surpassing mere convenience or cost considerations. With reduced turnaround times, lowered expenses, and minimized waste, the advantages are clear. Our facility now offers end-to-end services, from development to production, ensuring optimal quality and cost-effectiveness for our valued clients.